Sheet metal work and further processing services

We always base our operations on the needs of our customers, and we tailor our cutting and finishing services to a wide range of industries.

Our efficient and modern equipment allows for a successful production process and a detailed end result in both large and small series.

Bending

We provide precise and high-quality bending of metal sheets using six press brakes with capacities ranging from 32 to 320 tons and a maximum bending width of 4 meters.

For smaller parts, we utilize a robotic bending cell to enhance cost-efficiency for large production runs.

Rolling

We offer cylinder and cone manufacturing services with two 4-roll CNC rolling machines. With a working width of 2 meters and a maximum thickness of 16 mm, we ensure precision in creating a wide range of geometries and dimensions.

Welding

TIG welding is ideal for thin materials and applications requiring precision, while MIG welding provides speed and efficiency for larger projects, such as industrial structures and automotive manufacturing.

Threading

Threading is a process used to create threads on metal surfaces, enabling parts to be fastened and connected. This method is particularly valuable for producing precisely sized and durable threads for components ranging from M3 to M33.

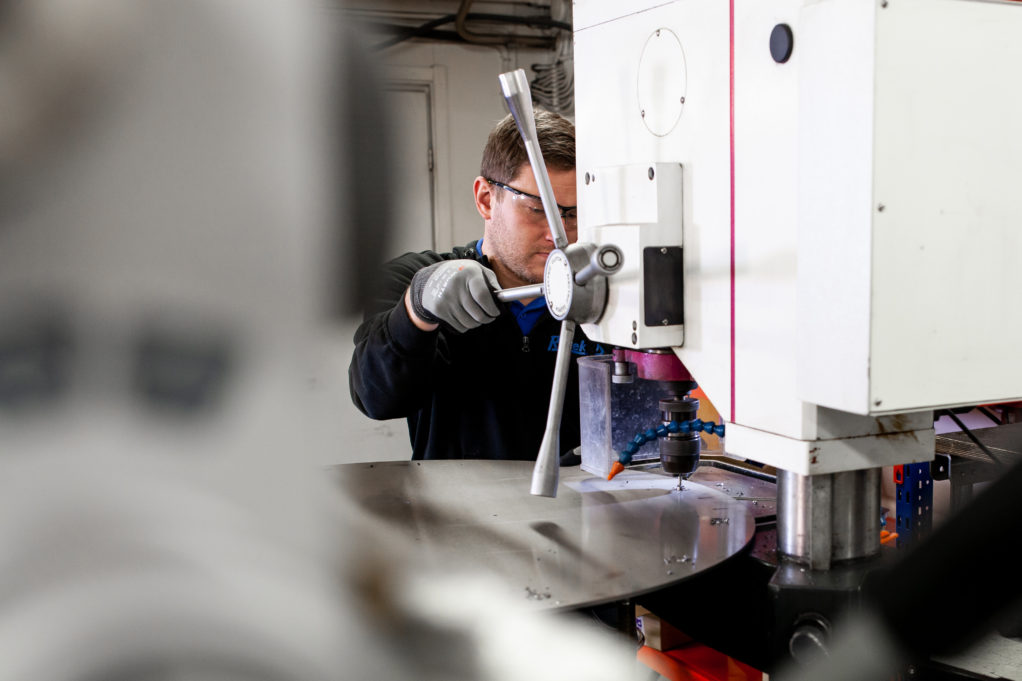

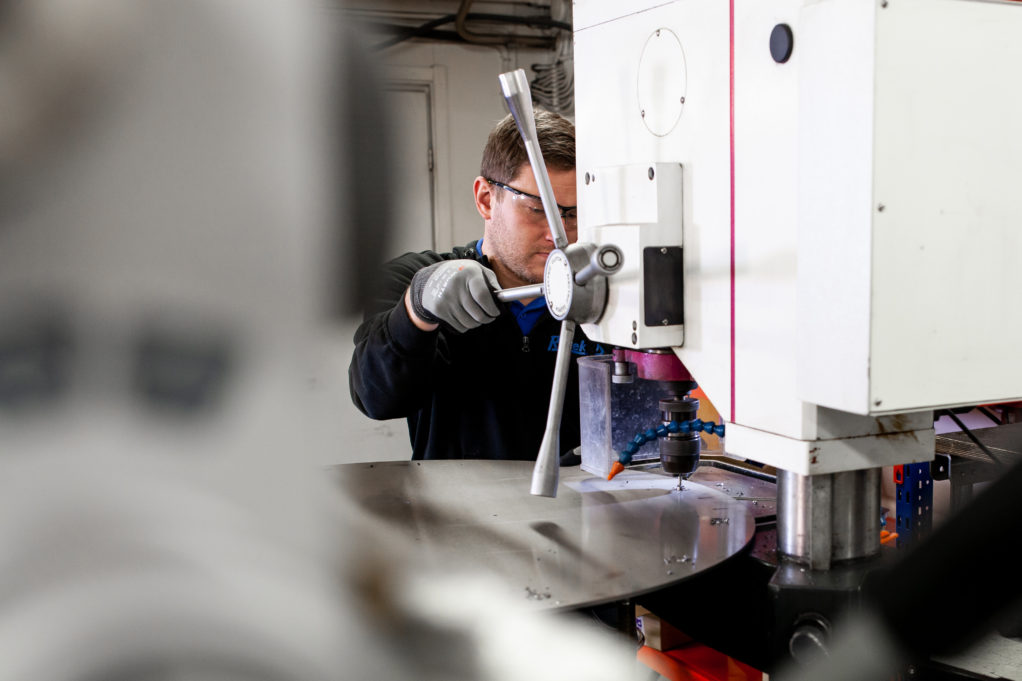

Countersinking and Drilling

With countersinking and drilling, we ensure a polished finish for components, creating clean holes and small threads even in thicker sheets—achieving results that cannot be obtained through cutting alone.

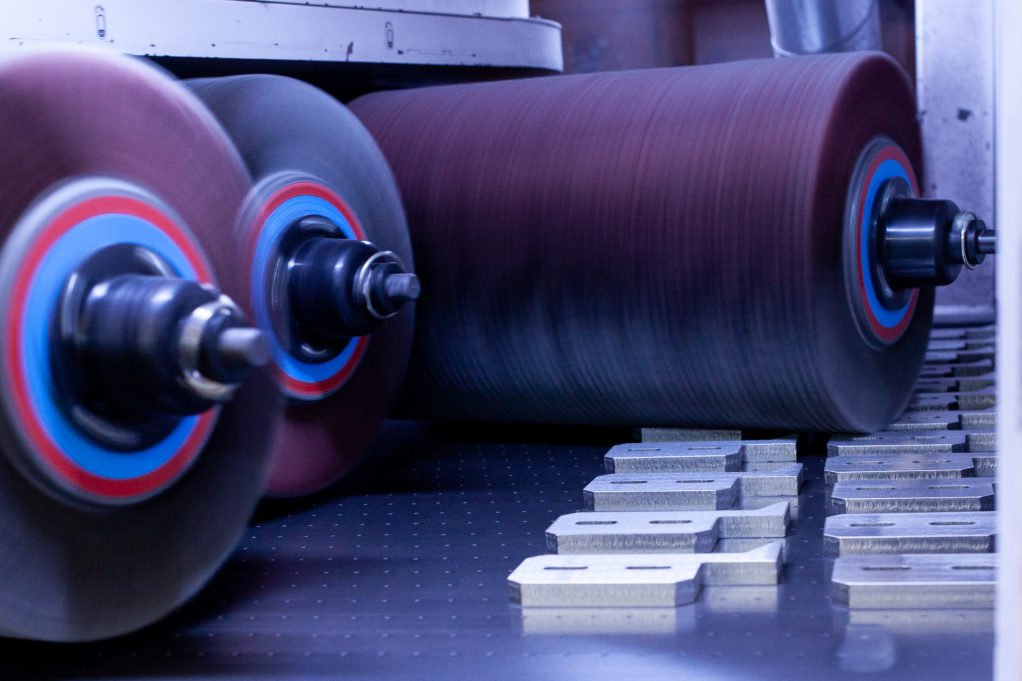

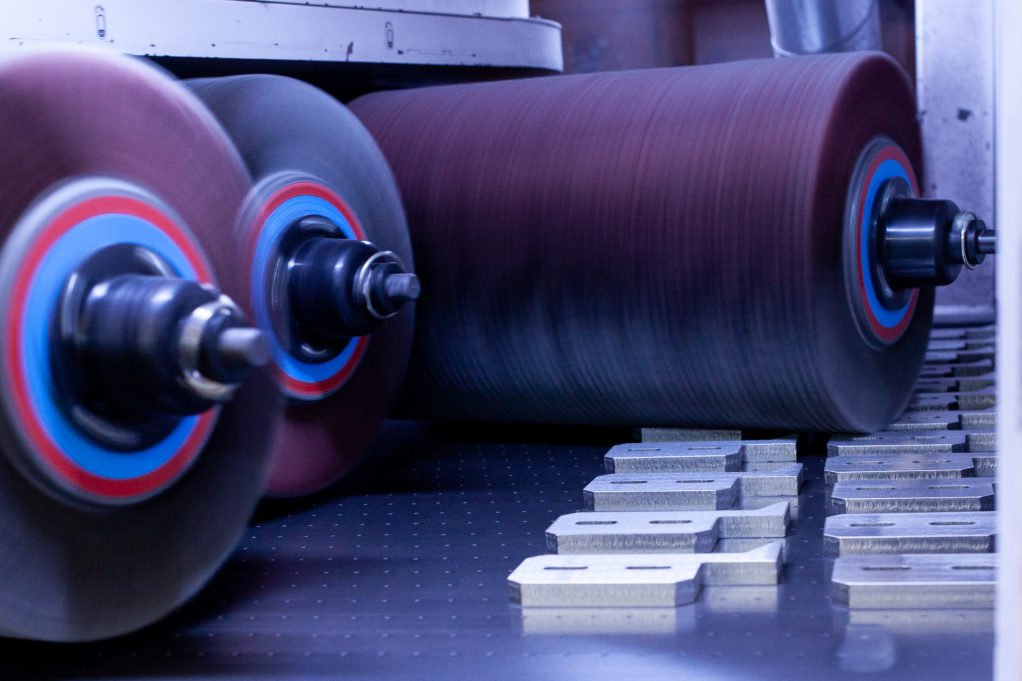

Grinding Line

We provide top-tier finishing for metal components with our Timesaver grinding line, offering a working width of 1.6 meters. The line enables rounding edges up to R2 for laser-cut pieces.

Grinding enhances the quality of paintable components and improves workplace safety, delivering clean and flawless final products.

Riveting and Pemming

Riveting and pemming are methods for securely and reliably joining metal components.

Riveting involves fastening parts together with rivets, providing a strong and durable connection, especially for thin materials. Pemming uses specialized riveting techniques that allow fasteners to be installed directly into sheet metal without pre-drilling.

Let’s design a solution that suits your needs

It all starts with good planning. If you need help to bring your innovation or product to life, we’re here to help you from design and production to finishing touches.

Our design service supports our customers’ needs for sheet metal work and metal components. We help you optimise the functionality, manufacturability and cost-effectiveness of your product at an early stage. Our modern equipment and years of experience guarantee a solution that meets your most demanding technical requirements.