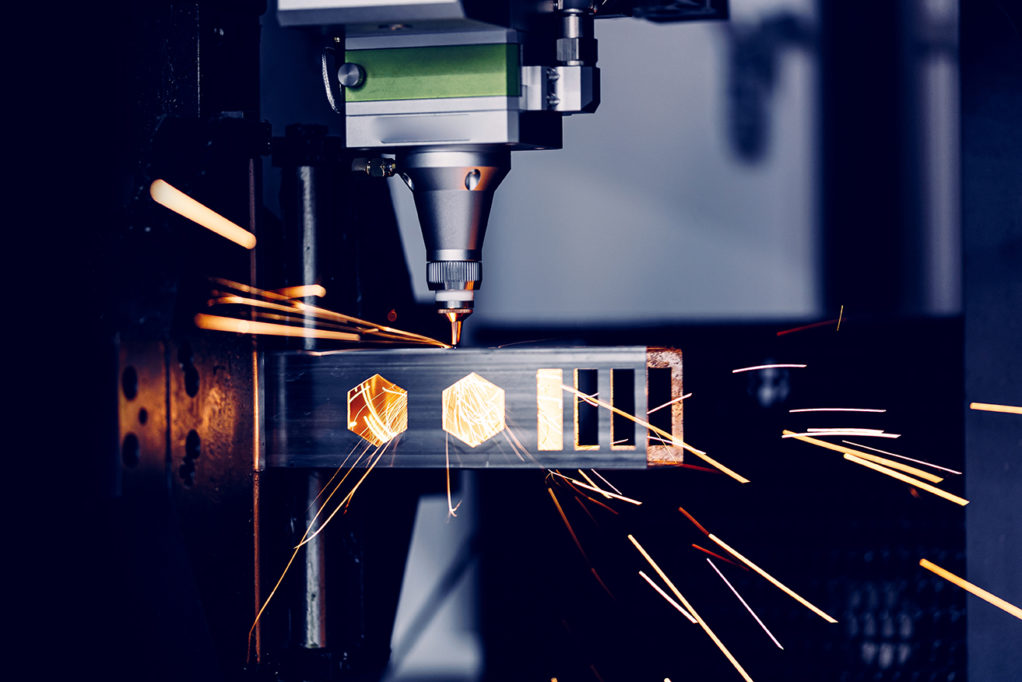

Pipe machining with pipe laser

3D laser cutting is the most advanced method on the market, standing out for its speed, precision and freedom of design.

3D laser cutting can be used to create complex notches, pipe end shapes, weld bevels and through-hole finishes on pipes and profiles – fully automatically, quickly and with extreme precision, with a high quality cut.

Compared to traditional methods, which require multiple operations such as drilling, turning, punching, milling, sawing and deburring for the same job, laser cutting offers considerable efficiency and simplicity.

The cost-effectiveness of the tube laser

The tube laser replaces several traditional operations, providing excellent cut quality in a single operation.

As a manufacturing method, the tube laser is also cost-effective for low-volume production and prototype trials. By manufacturing the product in a single step, it allows the product to be easily integrated into the customer’s other manufacturing processes. In addition, the number of parts and wasted material is reduced, assembly accuracy is improved and the lead time of the production process is shortened.

Pipe bending

Tube bending is the process of precisely shaping metal tubes into different angles and shapes.

By bending the pipe, we can create the most challenging shape in the pipe, which reduces welding and the need for finishing. When no extra steps are taken, it ensures a faster turnaround time in production.